At this point I should really be wrapping up everything and start delivering the first units, but as I was preparing the front cover files for the factory I couldn’t help adding a nice new feature.

Security, OpenWRT and storage

Tales of security woes over the years made me a bit paranoid about the various vulnerabilities I could expose my users to, so in the development of Prism I wanted to make everything as secure as possible without breaking the bank.

A quick recap

Today is the deadline for the HackADay Prize contest, and that’s a great chance to write a recap article about Prism.

OpenEnergyMonitor, Node-Red, MQTT

All that effort to build a connected charging station brought its first victory as we were finally able to regulate charging based on the solar energy available. Since we had issues with our solar installation (panels are installed, but we’re still waiting for the bureaucrats approval and meter installation to activate them), we went to a friends house to experiment with his installation.

Front cover protection and dealing with suppliers

At the end of the front cover post I mentioned that we were working with a plastic sheet supplier to design an adhesive protector for the cover. I was pretty excited when I got the package today, but that excitement quickly turned into rage and frustration as soon as I opened it: the parts that should have been transparent are red instead.

Continue reading Front cover protection and dealing with suppliers

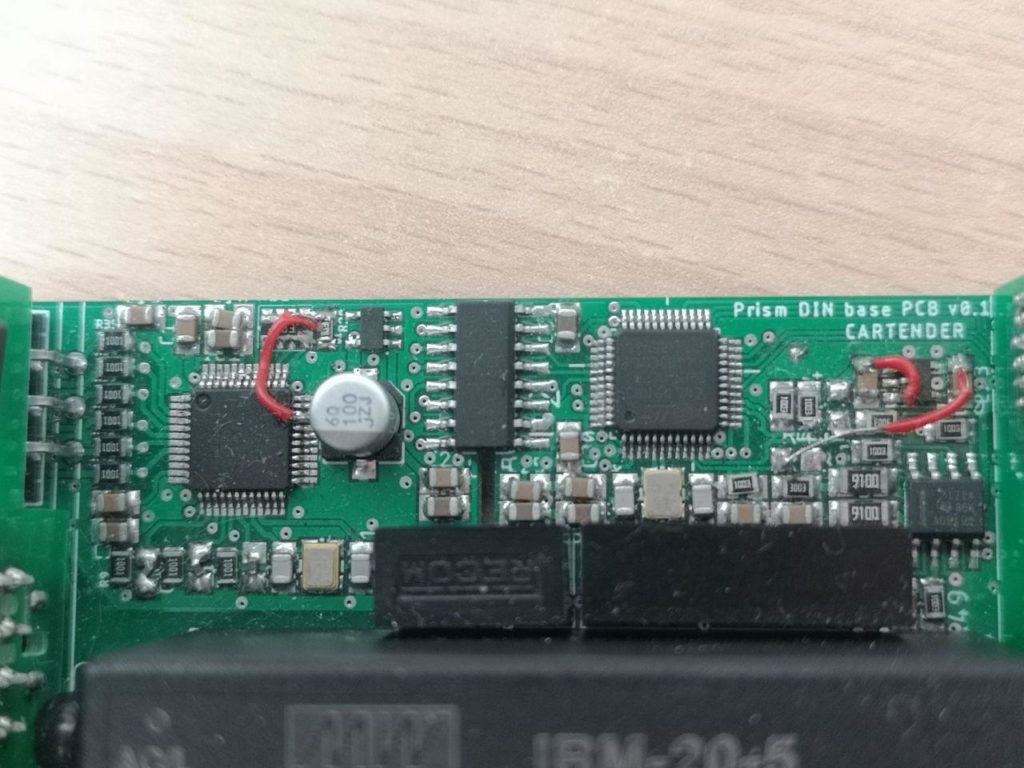

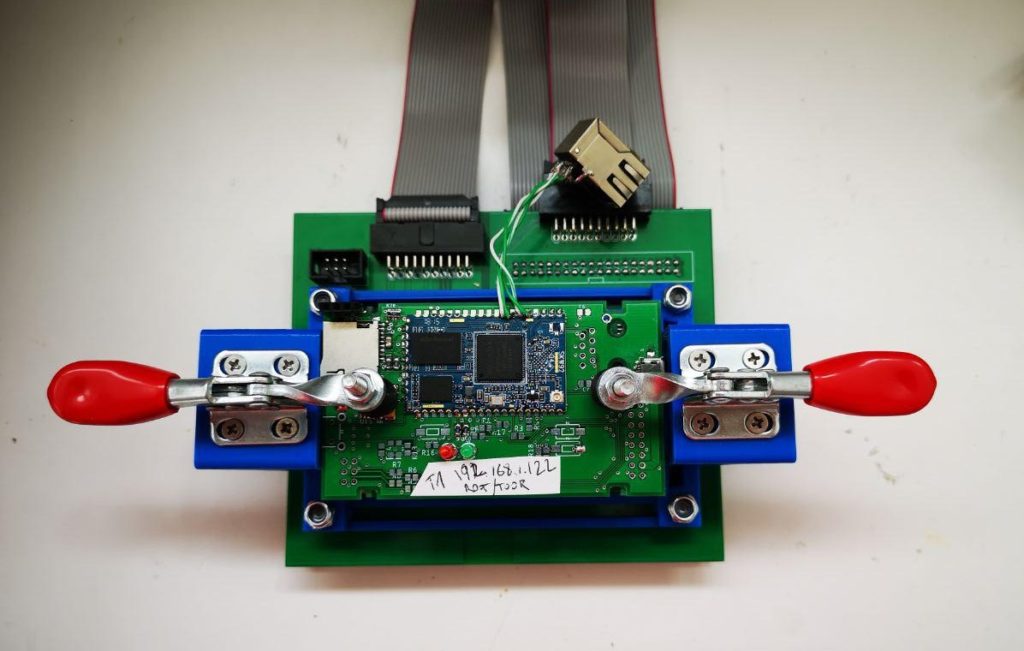

Board testing: it’s fun, they said

This post is written by my friend (and now colleague/intern :) ) [Michele], who worked on the test board. I assigned him this task as it’s the best way to learn about the boards and get up to speed with the project. It also seemed a great way to test the really interesting Exclave project from [bunnie], but -spoiler alert- we’ll have to wait for that.

After manufacturing the boards, we need to test them to make sure that the assembly house built them correctly. This is my first time designing a nail bed, however the task seems quite simple. I have to test the following:

- Short circuits

- Voltage levels from the various power supplies

- Current consumption

- Communication (RS485, I2C, SPI …)

- Other signals to and from the board

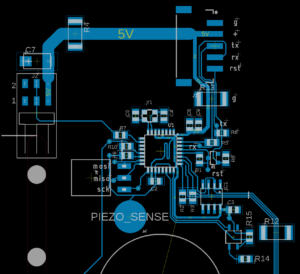

Prism Core boards

Now that I tested and improved the proof of concepts for power, energy measurement, control and car interfacing, I can merge everything in a single block that fits in a nice box. As discussed in the enclosure post, I choose to use a 3DIN standard box so I looked around for options.

Now that I tested and improved the proof of concepts for power, energy measurement, control and car interfacing, I can merge everything in a single block that fits in a nice box. As discussed in the enclosure post, I choose to use a 3DIN standard box so I looked around for options.

My 2 cents for Linux

While I am definitely a hardware guy, I also really like to write software, either as the firmware for the devices I build or as quick hacks to improve my daily routines. I’ve always been a Windows guy because all electronics development software was only available for that platform until recently, and I have a love/hate relationship with Linux: I tried many times to use it as my main OS, but I always had to revert to windows for one reason or another (but mostly laziness, I must admit).

RCM direct current sensing – how it’s done

This post is written by my friend (and now colleague/intern :) ) Michele.

Our target users for Prism are mostly hackers and passionate people playing around with EV technology; for this reason we strive to make Prism as safe as possible even for the most edge cases.

Front cover

We thought a lot about the user interface for our charging station. After ditching the infinite mirror idea, we wanted something simple and elegant, inspired from the Tesla wall charger, so we started experimenting with RGB LEDs strips. The first version of the cover for the plastic case was a laser-cut polycarbonate sheet, with a LED-strip taped to the back: